Pushbutton

Posted in Planning , on

One of the things that complicated our assembly was the question of how to make the only man-machine interface on DURR Beta; the pushbutton on its side.

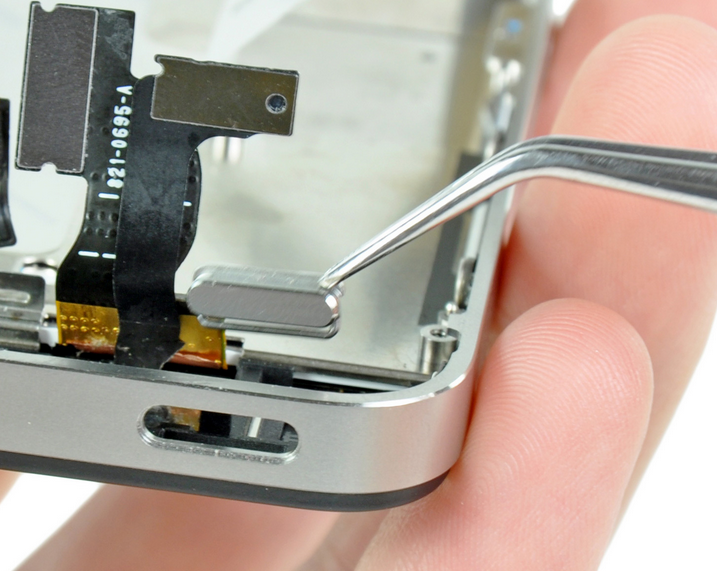

In most products with buttons, like a mobile phone, you have a teeny tiny plastic/ metal inset that is the pushbutton interface. This is in order to access the PCB's actual pushbutton through a casing's wall thickness, but also to style the button; shape, materials, add graphics, etc.

This piece is often so small (our button is 3.2 mm in diameter and 2.2 mm in length) that it usually needs high volume manufacturing techniques, like injection molding or forging. With other words, manufacturing techniques we couldn't afford. Also it couldn't be separately 3D-printed, because every service's guidelines on minimum part size (which we totally get).

[ image of an iPhone 4's lock button from iFixit ]

Other products, like e.g. many computer mice, use their casing material's flexibility in combination with cuts in the geometry; something we actually used for the Alpha version. Unfortunately, this was not an option for the Beta.

[image of the Alpha's pushbutton interface]

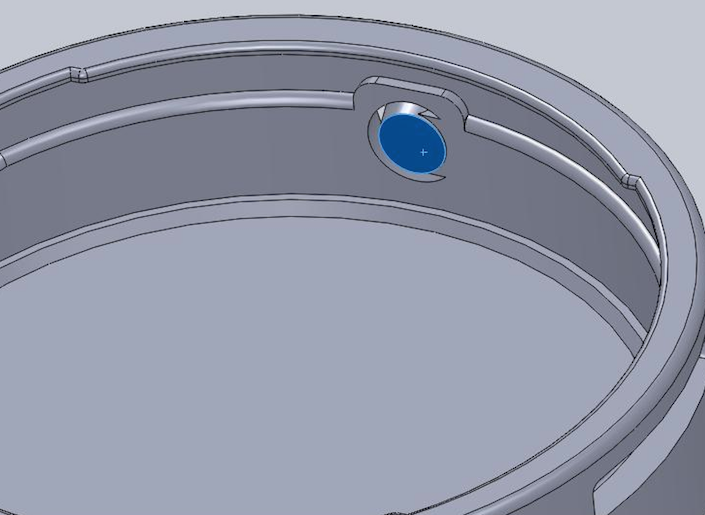

We chose to have the button interface in the same part as the back cover. It was a valid option; economic by sparing us an extra part, but complicated the assembly in a manner of ways:

· The stem, which the button was fixed to, needed to be flexible - but not so thin that it broke off during printing and handling. Touch and go stuff...

· The PCB needed to be fixed to the back cover and mounted inside the aluminum casing

together with

, not

before

, the back cover. Or else, you won't be able to insert the button. This at least did the alignment job for the PCB inside the body.

· When assembling the SLS back cover with PCB attached, the whole thing had to enter the casing tilted. This required extra accuracy and concentration during assembly, so the double sided insulating tape on the PCB didn't bond to the aluminum prematurely. Also, it resulted in a reduction of snap hooks in some areas.

· Cylinders (however tiny, our button is one) sintered perpendicular to the z-axis in the SLS machine chamber turns out rough. Yes, we knew... but it was a sensible trade-off.

· If the DURR unit needed to be disassembled, the button would be torn off, though staying in its place. The straps aren't replaceable and there's really no reason to open the back cover. Still, this isn't optimal.

[image of the Beta assembly]

[assembly is also shown ~1:18 in the work doc movie]

Ideally, the button would perhaps been a forged aluminum button, maybe anodized in the same color as casing and buckle... Anyhow, SLS plastic is nice, tho in a side-by-side comparison to the slick aluminum, it's ... basically up to snuff.

All in all, we're happy with the pushbutton and how the assembly worked out, especially for our budget and volume!

Presale - On counting chickens

Posted in Planning , on

Up until late May, actually the day before we would have launched our pre-order, we were convinced by accumulated assumptions that a pre-order was a good idea for us. In retrospect we're very happy with our change of minds.

Our situation at the time was probably quite similar to companies that has done crowd-funding campaigns, or companies who has announced a product before it reaches market;

DURR Alpha

was old news – the idea was communicated, and we just wanted our damn thing ready for sale. However, in the process of designing for manufacturing there are a myriad of details and decisions that continuously arise, always moving the finishing line. Which in turn makes it very, very tempting to open a pre-order. The pre-order will capture your current internet mojo by capturing the customers money - before the product is fit for sale. Tempting... The service we considered was the popular

Celery

. It integrates great with

Shopify

, plus it seems quite easy to use and manage. Despite the alluring promise, we found ourselves nervous and at our toes before the pre-launch. So, we sat down and weighted the pros and cons of pre-orders. Our case and point of view might differ from most other companies, but it became clear to us not to start counting chickens, and thereby ditching the pre-order. This is how we saw it:

Pros

· Bagging online traction:

This is already mentioned, but perhaps the biggest pro. We were lucky and had great coverage on DURR Alpha, not just on US gadget blogs, but worldwide and from different angles. For each day the Beta was not for sale we felt the clock ticking, and the attention dwindle. This becomes an increasing risk of lost income. At Skrekkøgle we fund our own projects, and so we invested all of our hard-earned cash, on expensive production that might not turn out profitable. The pre-order could have been able to ease the concerns of our ever shrinking bank account.

· Adjusting volume:

Earlier we had been talking about how the pre-order would be a good tool for predicting the demand for the Beta version, and thereafter adjusting the volume of pieces. However, in our case it quickly became quite clear that the volume was already set for us, due to minimum count at production facilities, and of course, economy. Still, you could make a solid case for this argument.

· A/B testing:

Another thing that's definitely valid is using a pre-order as an A/B testing tool. What finish or color do most people prefer? Or even, could you get some interesting feedback that could be implemented, changed or fixed before the product's launched? We imagined this being helpful for ruling out issues, but most relevant for

DURR Beta

, prevent us from sitting on boxes full of our weird favorite colors.

Cons

· Cost:

Pre-order is expensive. Even though a 2% fee seems little at first glance, it quickly becomes a lot of money, and actually a big expense. And especially when all these percentage fees are adding up; PayPal 2.9% + Shopify 0,5-2,0%, + others? We contacted Celery asking about their volume discounts, but those were negligible differences for volumes far beyond our own. Monthly plans for short term pre-orders were also mainly for bigger merchants and bigger monthly loads.

· Cash in limbo:

Another deal-breaker for us is that you can't access the money from your pre-ordering customers. The cash is in this limbo state, where they're reserved and held by the pre-order service at hand, until you are ready to ship and thereby fit to capture the payment. Fair enough. Guess this might be obvious for most business minded people, but it wasn't quite clear to us. So all that money, reassuring as it might be, can't be spent for development, promotion, etc. and will therefore help you very little financially.

· Customer pressure:

Promising something to people can be very stressful. And, it can be very time consuming. If you trade your customer's cash with a pretty picture, keep in mind that many will be excited, an excitement that can quickly turns to impatience. Even though we haven't made many promises, for e.g. dates, prices, etc. we've used many hours every week answering mails from eager and itching customers. Which is super nice, don't misunderstand, but still time and energy consuming. So, if you're stressing to get your product out on the market, we'd guess the last thing you want is hundreds of people breathing down your neck.

· Unfinished product?

The product at hand might not be entirely finished, either cosmetically, software-wise, promotionally, or other. Once something is launched (unless in a drawing-board kinda way), it will probably be perceived as finished. And the customers who are buying into that product may not approve of your later changes in aesthetics, behavior or story. This could also be the case for the selling price; perhaps the production or development suddenly took an expensive turn and your current price doesn't quite cover the costs.

Again, we admit to being biased, these observations are based on our impressions, opinions, and of course our

own product

's case. Nevertheless, we were happy to skip the pre-order and rather wait for all the pieces to fall into place.

If you have other opinions or points of view, please

send us a note

!

CART (0)

CART (0)